Caterpillar recently rolled out EMSolutions, a new equipment management solutions program aimed at helping fleet managers cut unnecessary costs, including fuel and labor expenses. That’s not the only benefit EMSolutions brings to the table, however. Cat’s new equipment management solutions product helps achieve four specific business objectives: control costs, improve operations, manage people, and reduce risk. Cat’s EMSolutions utilizes the latest technology, offering specialized advice and targeted services for customers’ business needs.

EQUIPMENT MANAGEMENT: THE STANDARD

While equipment management may sound like an easy task, any fleet owner—big or small—would tell you otherwise. The goal of equipment management is to make sure your machines are delivering the maximum performance for the minimum cost. The key requirements to focus on in order to achieve proper equipment management are machine performance, machine health, planned maintenance and repair, and safety and security.

Keeping a machine, or machine systems, at optimal performance standards increases uptime and minimalizes operating costs. The same can be said for a healthy machine; less time in a shop means more productivity and fewer costly surprises. Planned maintenance and repairs allow you not only to keep your machine running in optimal condition, but also to choose the service maintenance schedule. This minimalizes down time by helping to identify and fix small problems before major failures occur, decreasing unscheduled downtime. Finally, properly maintained machines are safer and less at risk of being involved in an accident, while tracking and monitoring machine locations and usage keep security tight.

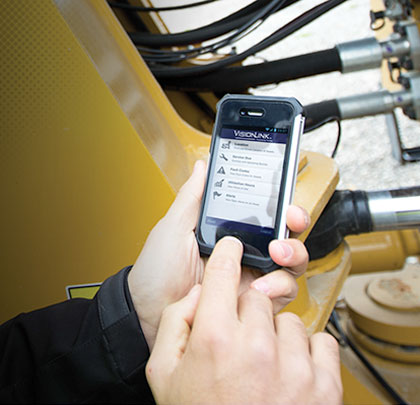

The good news is, you don’t have to keep track of your fleet maintenance alone. The technologies built into Cat’s construction equipment easily gather immediate and accurate information about your machines, including location, health, maintenance needs, and more. You can access all the information straight through Cat’s VisionLink® web or mobile. The best part might even be that VisionLink’s advanced software takes care of most of the analytics for you, allowing you to focus on other important parts of your business.

Equipment management can help improve efficiencies by monitoring machine utilization, logistics, equipment wear and tear, when to take a machine for service or preventive maintenance.

EQUIPMENT MANAGEMENT: THE EXTRAS

There are four specific bonuses to equipment management. The first is controlling costs. Having accurate cost tracking can give you the foundation to analyze repair and maintenance schedules. Furthermore, you can see your real estate costs, which may allow you to take the necessary steps to lower them. Other cost controlling advantages of equipment management include identifying problems; prioritizing and streamlining tasks; providing the data to better manage labor, fuel, maintenance, and repair expenses; and offering reporting functions to find and eliminate excess idle time.

Improving operations is another bonus feature of equipment management; knowing the location of your machines and when they are due for maintenance allows you to make more informed operational (and cost effective) decisions. Equipment management can help you to improve efficiencies by monitoring productive work time and machine utilization, logistics, equipment wear and tear, and team responsiveness. Based on equipment management, you can decide when to take a machine for service or preventive maintenance. It also gives you a better idea of how to move your fleet around between jobsites—making sure the right machine is in the right place at the right time.

Machines aren’t the only factor you have to be concerned with as an owner or as a manager. Despite the nomenclature, “equipment management” can also help in people management. Worthy equipment management solutions take into account the machine operators. Cat’s Product Link® is made specifically for this purpose. Product Link keeps you up to date about your operators’ performance habits and shows the frequency of operator events, which will allow you to see if additional training is necessary. With Product Link, you can manage other groups in your organization to see more easily how to allocate service personnel. Tracking operators, training, and company culture allows you to see how your assets are being handled and how motivated your employees are to help your business succeed.

Finally, equipment management can lead to risk reduction. Imagine loosing $1 billion worth of equipment and tools. Now increase that number by 20 percent every year with a recovery rate of only 10 percent across the board. This set of statistics comes straight from the National Insurance Crime Bureau and National Equipment Register concerning the construction industry. That’s a major risk. And only one that equipment management can help avoid. Cat’s EMSolutions helps reduce risk by aiding in regulation compliance; replacing machines at the most convenient time for you; keeping machines in working condition to reduce accident and injury; and helping to maintain maximum fleet availability for fast response to unexpected delays.

YOUR NEW BEST FRIEND

Cat works diligently to introduce its customers to not only the best products, but also the best technology focused on jobsite solutions. Cat’s technology promises a jobsite of the future, allowing customers to take control of the jobsite through Cat Connect EMSolutions and Automation & Productivity Solution. Utilizing these technologies will help to optimize operations in dynamic construction applications. Cat is also focused on offering automated, semi-autonomous, an autonomous jobsites, allowing for minimal input on-site across the board. ■

For More Information: Caterpillar consistently innovates and refines advanced technologies to help make equipment more productive and efficient, from advanced engine technologies to in-cab monitoring and machine health management to fleet-wide information systems. For more about EMSolutions, visit www.cat.com/en_US/support/operations/technology.

_________________________________________________________________________

Modern Contractor Solutions, August 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.

EMSolutions Covers Many Bases