Which will keep you warmer when you’re working outside, a dry shirt or a damp shirt?

All of us know from experience that damp clothing—from sweat, rain, etc.—obviously is much colder, but we might not know why that’s the case. The reason provides an important lesson for helping ensure a building’s insulation does its job.

In short, clothing keeps you warm by trapping air warmed by your body, next to your skin. In contrast, wet clothing sticks to you, and as water is a better conductor of heat than air, the damp fabric provides a direct path for heat to flow away from your body.

The same thing happens in building envelopes. Insulation helps block heat from escaping, but any breaks in the insulation provide a path for heat to travel out of the building—wasting energy. In a wall assembly, these paths (thermal bridges) include wall studs and exterior cladding attachment systems that conduct heat more readily than the insulation does.

Because thermal bridges—like a wet shirt—reduce the building envelope’s thermal performance, building codes in the U.S. require continuous insulation in most commercial buildings.

ASHRAE 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings, defines continuous insulation (CI) as: “Insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings.”

Common methods for attaching exterior wall cladding often penetrate the code-required CI layer, and thus provide a thermal bridge. Reducing these thermal bridges is crucial for ensuring the CI delivers on its promise of providing a comfortable and energy-efficient building, which are two key goals for any building owner.

All images courtesy of Hunter Panels

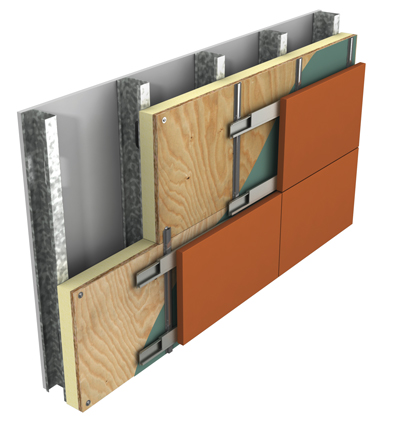

Featured Image: Composite insulation panels, such as Hunter Xci Ply, provide continuous insulation with fewer thermal breaks than other cladding attachment systems.

Above: Composite insulation panels require fewer fasteners than other cladding attachment systems, so reduce thermal bridging.

CLADDING ATTACHMENT SYSTEMS AND THERMAL BRIDGING

Contractors have several methods for attaching exterior wall cladding, most of which penetrate the CI. These have become more sophisticated over time, with the goal of providing adequate support for the cladding, yet reducing thermal bridges. Common cladding attachment systems include:

- Steel Z girts

- Rail systems

- Clips

- Composite Z girts

Steel Z girts essentially extend the wall studs outward beyond the insulation layer. Advantages include ease of use, and a large surface area to attach the cladding to. Yet, the significant amounts of steel involved create thermal bridges.

Rail systems reduce the thermal bridging inherent with steel Z girts by placing the rails over the CI layer and screwing through the insulation. As with girts, rails provide a large area for attaching cladding. Price and complexity of installation vary by product.

Clips typically are either an abbreviated composite girt returning to stud non-continuously, or a small member attached back to the studs through the insulation. The cladding is then attached to horizontal or vertical rails fastened outside the insulation to the clips.

Composite Z girts work in much the same way as steel Z girts, but address thermal bridging by using materials with lower heat flow than steel. A potential trade-off with some systems is the specialized installation details.

CONTINUOUS INSULATION, CONTINUOUS CLADDING ATTACHMENT POINTS

In light of the thermal bridges created by cladding attachment systems, insulation manufacturers have developed products that provide both continuous insulation and continuous attachment points for cladding.

Fastening requirements for composite insulation products depend on the base wall type, framing spacing (for stud walls), insulation thickness, and cladding weight.

For example, Hunter Panels Xci Ply is made of polyisocyanurate rigid foam insulation bonded to plywood or oriented strand board (OSB). In such composite insulation panels, the entire plywood or OSB surface can be used as a cladding attachment point, which greatly simplifies cladding installation. Additionally, while the composite insulation panel is secured firmly to the base wall, the cladding attachment is thermally broken by being attached to the wood of the composite panel. Fire treated plywood can be used when the NFPA 285 fire test is required.

WORKING WITH COMPOSITE INSULATION PANELS

Composite insulation manufacturers typically specify how their products should be attached to the base wall system, to ensure adequate support of both the insulation and the exterior cladding.

The number of fasteners and fastening pattern required depend on the wall type (wood stud, steel stud, concrete, CMU), stud spacing, insulation thickness, and cladding weight. The fastening schedule also might vary if the composite insulation panels are installed horizontally or vertically, so it is important to confirm details with the manufacturer. Insulation manufacturers also usually specify which types of fasteners are required determined by the base wall type, steel or wood studs, concrete or CMU.

CONCLUSION

A wall’s energy performance depends on the entire assembly, not just the insulation in it. The effectiveness of even the highest R-value insulation is reduced by thermal bridges. To help ensure a comfortable and energy-efficient building, it is important to pay attention to all details in the assembly, including how the exterior cladding is attached. Composite insulation panels offer a way to minimize thermal bridging while simplifying cladding attachment. ■

About the Author: MacGregor Pierce is the Xci product manager for Hunter Panels. A division of Carlisle Construction Materials, Hunter Panels is a leading manufacturer of polyisocyanurate insulation. For more, visit www.hunterpanels.com.

_________________________________________________________________________

Modern Contractor Solutions, March 2017

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.