On May 4, 2015, OSHA released its long-pending 162-page final rule establishing a confined space standard for the construction industry. The rule, which takes effect on August 3, 2015, largely tracks the agency’s general industry standard, but also borrows from consensus standard ANSI Z117 and includes provisions reflecting technological advances, such as the ability to conduct continuous atmospheric monitoring. The standard is codified at 29 CFR Part 1926.1200 through 1213. A lawsuit was filed on May 14, 2015, by the Texas Association of Builders, who have asked the US Court of Appeals for the Fifth Circuit to throw the rule out, claiming: “OSHA’s final rule is arbitrary and capricious, not supported by substantial evidence in the record, considered as a whole, an abuse of discretion, or otherwise not in accordance with law.”

Currently, OSHA generally enforces safety hazards in construction-sector confined spaces either through Part 1926.21 (employee training on hazards involved with a task, necessary precautions, and personal protective equipment) or via the General Duty Clause (Section 5(a)(1) of the OSH Act) as a “recognized hazard.” Now that there is a specific confined space rule, enforcement under the General Duty Clause should cease.

DEFINING CONFINED SPACES

Confined spaces—such as manholes, crawl spaces, and tanks—are not designed for continuous occupancy and are difficult to exit in the event of an emergency. They also can have dangerous atmospheres (including gases, chemicals, carbon monoxide, or oxygen depletion). In addition to exposure to toxic substances, workers in confined spaces face life-threatening hazards, including engulfment, electrocutions, explosions, and asphyxiation.

Construction workers often perform tasks in confined spaces—work areas that (1) are large enough for an employee to enter, (2) have limited means of entry or exit, and (3) are not designed for continuous occupancy. These spaces can present physical and atmospheric hazards that can be prevented if addressed prior to entering the space to perform work. The new rule creates a permit program that employers must follow for those areas classified as “permit required confined spaces” (PRCS).

The final rule affects establishments involved with building, highway construction, bridges, tunnels, utility lines, and other projects requiring work in areas that meet the definition of confined space. Both general contractors and specialty trades will be covered, including those in residential construction work.

COST OF COMPLIANCE

OSHA estimates that 5 fatalities and 780 injuries per year would be prevented, with associated savings of $93.6 million per year. The compliance cost per year will be approximately $60 million across all construction sectors. Most of the cost is associated with the employer’s obligation to evaluate confined spaces, classify them, and exchange of information with various entities, but there are extra costs arising from atmospheric monitoring requirements, training, rescue capability, written program requirements, permits and review procedures, attendants, ventilation, and hazard isolation. OSHA represents in its preamble that the rule is deemed “economically feasible in every affected industry sector.”

RULE’S SCOPE

In the rule’s Scope, OSHA clarifies that examples of confined spaces in construction include (but are not limited to): bins, boilers, pits, manholes, tanks, incinerators, scrubbers, HVAC ducts, concrete pier columns, transformer vaults, water mains, precast concrete and other pre-formed units, drilled shafts, enclosed beams, vessels, digesters, lift stations, cesspools, silos, air receivers, turbines, baghouses, and mixers/reactors. However, the standard does not apply to excavations covered under Subpart P, to diving construction activities under Subpart Y, or to underground construction covered by Subpart S. OSHA notes that where the new rule applies and there is a provision that addresses a confined space hazard in another applicable OSHA standard, both rules must be followed.

The standard defines “permit-required confined space” as one with at least one of the following characteristics: (1) contains or has the potential to contain a hazardous atmosphere; (2) contains a material that has the potential for engulfing an entrant; (3) has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor that slopes downward and tapers to a smaller cross-section; or (4) contains any other recognized serious safety or health hazard.

An “entry supervisor” is required and this must be a qualified person (employer, foreman, or crew chief) tasked with determining if acceptable entry conditions are present at a permit space, authorizing entry and overseeing entry operations, as well as terminating entry when required.

Everyone who is an “affected employee” must be trained, in both a language and vocabulary that the employee can understand, prior to performing assigned duties, or when assigned duties change or a change in hazards occurs. The training must establish proficiency in the assigned duties and employers must maintain training records that list the employee and trainer(s) names and date of training. The records must be maintained as long as the worker is an employee.

WHAT THIS MEANS

In essence, before workers can enter a confined space, the employer must provide pre-entry planning that includes evaluation of the space, identification of means of entry and exit, proper ventilation methods, and elimination or control of all potential hazards in the space. The atmosphere must be tested and all hazards must be continuously monitored, rescue procedures must be determined (along with necessary equipment), and if air is not safe for workers, proper protections must be made available. Written programs are required for all PRCSs.

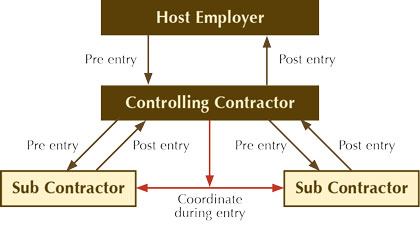

If a general contractor hires a subcontractor to do confined space work, the two entities must discuss spaces on the site and their hazards before and after entry. OSHA has the right to cite both employers for the other’s violations under its Multi-Employer Worksite doctrine.

The rule will initially affect companies in states with federal OSHA programs, but all state-plan states will have to adopt the new standard or one more stringent. The rule is quite complex and more information can be found at www.osha.gov. ■

About The Author: Adele L. Abrams, Esq., CMSP, is an attorney and safety professional who is president of the Law Office of Adele L. Abrams PC, a ten-attorney firm that represents employees in OSHA and MSHA matters nationwide. The firm also provides occupational safety and health consultation, training, and auditing services. For more information, visit www.safety-law.com.

_________________________________________________________________________

Modern Contractor Solutions, June 2015

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.

OSHA’s Confined Space Rule Puts Pressure on Contractors