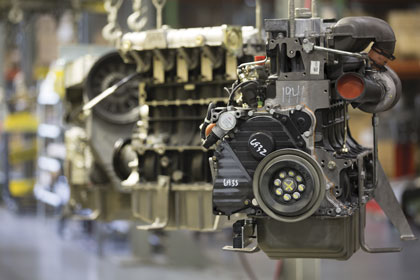

DEUTZ Corporation will provide JLG Industries, Inc., an Oshkosh Corporation Company, with DEUTZ Xchange remanufactured engines for JLG’s aerial work platform (AWP) reconditioning program.

“JLG was particularly pleased with the 3-year transferrable warranty that we offer on all our DEUTZ Xchange engines,” says Robert Mann, DEUTZ Corporation’s president and CEO. “That warranty, our quality product, and the fact that our remanufactured engines can be serviced by any DEUTZ distributor were key factors that helped us earn this business.”

According to Christopher Mellott, JLG Industries vice president of aftermarket sales in North America, the JLG reconditioning program is a leader in the lift and access, construction, and rental industries, thanks in large part to the scope of work. “JLG has very strict OEM guidelines that we follow for all of our reconditioned products. Our scope of work is very detailed, making our reconditioning program similar to our new manufacturing program. In the end, customers receive a machine that has the same reliability as a new one.”

THE PROGRAM

As part of the reconditioning program, AWP engines are remanufactured or resealed, and the machine’s boom is refurbished. This program provides buyers looking to grow their fleets or replace worn equipment with another option at approximately half the cost of a new unit. It also reduces the amount of material destined for landfills, saving 12 tons of steel, water, and other resources when compared to manufacturing a new machine.

“We were looking for a global partner that could support our growth and provide quality product and support,” says Mellott. “Selecting DEUTZ offered us the ability to partner with the leading engine OEM to deliver the consistency and reliability we know our customers have come to expect.”

FACILITY INCREASED PRODUCTION

To supply JLG with enough remanufactured engines for its reconditioning program, DEUTZ’s Pendergrass, Georgia, facility has increased production from approximately five engines per day to eight. A streamlined process will allow DEUTZ to deliver Xchange engines to JLG’s Bedford, Pennsylvania, facility on a just-in-time basis, controlling inventory costs while still meeting JLG customers’ expectations on turn-around time for their machines.

“We strongly believe in investing in the latest equipment and highly trained personnel,” says Michael Wellenzohn, a member of the DEUTZ AG board of management with responsibility for sales, service, and marketing. “Our new arrangement with JLG serves as a reminder that our commitment continues to provide results.”

The DEUTZ-JLG partnership has already begun to pay dividends for both companies. One of North America’s largest equipment rental companies purchased 137 reconditioned AWP units from JLG, explicitly requiring that DEUTZ Xchange engines be installed in each.

“We’re very excited about this program,” says Michael Klco, director of service sales for DEUTZ. “We strongly feel that this agreement with JLG is a testament to the detailed process we follow to provide top-quality remanufactured engines.”

ABOUT DEUTZ CORPORATION

For more than 150 years, DEUTZ engines have supplied customized, cost-effective power to a broad array of machine types and market segments. The nine millionth DEUTZ engine was produced in 2015. From its headquarters in Norcross, Georgia, DEUTZ Corporation, a subsidiary of DEUTZ AG, supports its product range of 30 to 700 hp diesel and natural gas engines. The company is committed to providing optimized power solutions from the drawing board to prototype to production release. The organization serves as a sales, service, parts, and application engineering center for the Americas, employing nearly 200 people. DEUTZ Corporation also operates a value-added production facility for some of its key OEM partners, as well as an engine remanufacturing facility in Pendergrass, Georgia. Strategically located DEUTZ Power Centers and Service Centers are designed uniquely support both OEM partners and end users.

ABOUT JLG INDUSTRIES, INC.

JLG Industries, Inc. is a world-leading designer, manufacturer, and marketer of access equipment. The Company’s diverse product portfolio includes leading brands such as JLG® aerial work platforms; JLG and SkyTrak® telehandlers; and an array of complementary accessories that increase the versatility and efficiency of these products. JLG is an Oshkosh Corporation company. ■

About the Author: For more information about JLG, visit www.jlg.com. To learn more about DEUTZ Corporation and its complete line of diesel and natural gas engines, visit www.deutzamericas.com.

_________________________________________________________________________

Modern Contractor Solutions – July 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.

Reconditioned & Ready