For decades, traditional smoke detectors have been used to protect commercial building occupants from the danger of smoke and fire—protection that is mandated by the NFPA (National Fire Protection Association).

Now, however, a new approach using more sophisticated, established smoke detection technology is contributing substantial benefits to building owners, managers: lower overall costs, earlier fire detection, a smaller footprint, and less disruption during NFPA mandated annual inspection and testing.

Contractors who are already offering and installing these new smoke detection systems are reporting increased revenues with the demand starting to rev up.

UNIVERSITY PROJECT

For Bob Pritchard of Convergint Technologies, a company that designs, installs, and services integrated building systems, including electronic security, fire alarm and life safety systems, a high-profile project for a new state-of-the-art sports performance center at a prominent Pac 12 university required a smoke detector that was less obvious, even concealable. Ideally, the system would also provide advanced smoke detection and be addressable so that the exact location of the alarm could be quickly identified for a quick response.

According to Pritchard, traditional smoke detectors tend to be large, often 7 inches or more in diameter, making them an eyesore when placed in every room. For commercial spaces where aesthetics are critical, spot smoke detectors can compete with the overall vision for the space.

“The designers and the architects responsible for this remodel didn’t want to see any safety devices sticking out of the ceilings,” explains Pritchard. “It was very important for them to see as minimal an impact as possible.”

Fortunately, Pritchard had experience installing Xtralis’ new VESDA-E VEA system and felt it would meet the architects’ requirements. Due to the VEA system’s aspirating smoke detection technology, the sampling points are much smaller than regular smoke detectors, so appear less obtrusive. They can even be fully concealed, for instance behind ventilation covers or within fixtures, making their presence visually unnoticeable to building occupants and visitors.

ASPIRATING TECHNOLOGY

In smoke detection, more advanced technologies that provide earlier warning detection exist. These systems work by aspirating—or drawing in air—from each room through small, flexible tubing. The air is then analyzed to identify the presence of minute smoke particles in a continuous process.

This is in stark contrast with the way traditional smoke detectors are designed. These devices are installed in each room or common space and connected to a central fire alarm panel by low voltage electrical wiring. When a significant amount of smoke accumulates in the chamber of the smoke detector, the alarm sounds.

“The VEA aspirating system is able to detect minor particles in the air much faster than a spot smoke detector, even before a fire starts to flame and burn,” Pritchard explains. “In many instances, this ability to get an early warning of a fire in one area can help prevent it from spreading to other areas.”

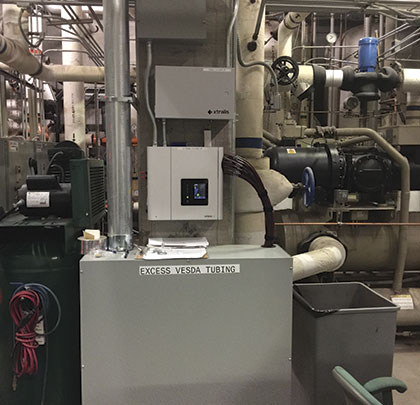

Featured Image: The VEA model consists of small, flexible tubes that draw air through small, unobtrusive sample points in each room. The air is analyzed using sophisticated laser-based technology at the central unit located within 300 feet.

Above: Due to the VEA system’s aspirating smoke detection technology, the sampling points are much smaller than regular smoke detectors, so appear less obtrusive.

TECHNOLOGY FOR SENSITIVE APPLICATIONS

For almost 40 years, aspirating smoke detectors have been used for the most sensitive applications where early detection of smoke or gas is critical, such as in cleanrooms, data centers, and telecom facilities.

The technology was first introduced in the early 1980s by Xtralis as the VESDA (Very Early Smoke Detection Apparatus) system.

The company now offers a VEA model that consists of small, flexible tubes that draw air through small, unobtrusive sample points in each room. The air is analyzed using sophisticated laser-based technology at the central unit located within 300 feet.

As a multi-channel, addressable system, the central unit can pinpoint the exact location of the alarm. A single system supports up to 40 sample points and can be extended to 120.

The system is also sophisticated enough to allow for three levels of sensitivity that can significantly reduce false alarms. For example, the system can differentiate a fire alarm triggered by someone smoking in a room from an alarm activated by a smoldering fire.

Even with these benefits, one of the primary advantages of an aspirating smoke detector system is its ease of maintenance, inspection, and servicing.

EASIER WAY TO TEST ALARMS

While spot smoke detectors are reliable and relatively easy to install, NFPA regulations also mandate annual inspection and testing of each unit for many facilities, including colleges and universities. This tedious and time-consuming process requires a fire alarm contractor to enter each room, introduce smoke directly into the detector, and verify that it functions properly. This is often covered under ongoing maintenance contracts where fire alarm contractors make a significant amount of their profit.

“The unique feature of the VEA system is that testing takes place back in the data closet where the central unit is located,” Pritchard says. “Not having to do the inspection out in the field saves a lot of time and causes much less disruption. There’s no need for me to stand on a ladder underneath each sample point and I’m not in people’s way.”

“Testing from the central unit also means you can perform the inspection at any time of day and the building occupants don’t even have to know about it,” Pritchard adds.

By some estimates, this inspection from a single location can greatly reduce maintenance and inspection costs and reduce the total cost of ownership of the fire alarm system by up to 60 percent.

As for installation of the sampling points on the ceilings, it is performed in a similar way as with other smoke detectors.

“The location of detectors doesn’t have to be any different from when installing regular smoke detectors,” Pritchard explains. “This was a very smooth installation and startup. The sample points were placed with the same spacing and following common paths of egress to ensure that the exit paths would not be contaminated with smoke.”

“As for the programming,” Pritchard continues. “It was pretty straightforward and the system is doing exactly what it’s supposed to do. The university is very happy with the way the product looks and works.”

For More Information:

For more information about Xtralis’ new VESDA-E VEA system, visit www.xtralis.com/vea.

_______________________________________________________________________

Modern Contractor Solutions, September 2017

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.