There is only one way to cook an egg … right? Of course not! There are many. But, some ways to cook an egg are better than others. Some can produce wonderful results while others may not. Chef and author David Chang once said, “The process and organization leading up to cooking the egg can tell you a lot about the cook.”

A chef learns to follow certain techniques to prepare excellent meals in a repeatable way. He or she knows there is a recommended sequence to follow that should have as little variation as possible. This repeatability of proper techniques is what separates the chef from the short order cook. Both stand over the grill and prepare food, but the chef’s end product is considered a culinary delight, while the short order cook’s end product squelches your hunger pains.

The range of difference between these two similar positions can be traced to the level of training. The chef was trained in culinary arts and how to apply these concepts and techniques. There was a step-by-step method for all phases of food preparation and cooking. The absence of this step-by-step sequence produces variation, not consistency.

ENSURING REPEATABILITY

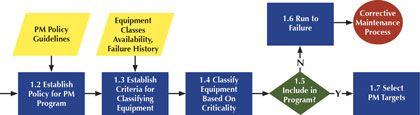

The method to ensure repeatability and final quality is a series of steps in a sequence called a process. These range from the tools, raw materials, seasonings, and the order of development. You can actually lay out the steps and decision points one at a time in the order of completion. We call this a process flow or process map.

A Process Flow Diagram (PFD) is a good way to visually lay out the steps and decisions in a process. The PFD chart provides a visual representation of the individual steps of a process in the order of occurrence. PFD charts are often referred to as Process Mapping, Flow Charting, or Flow Diagrams.

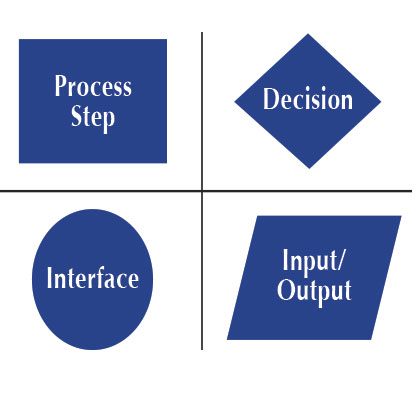

Example of flowchart with key symbols.

Constructing a flow chart is often one of the first activities of a process improvement effort, because of the following benefits:

- Provides everyone a clear understanding of the process

- Helps to identify non-value-added operations

- Aids to standardize the process

- Shows the order or sequence of activity

- Identifies problem areas and opportunities for improvement

- Provides a way to train employees

- Provides a means to study a process for improving it

- Provides an educational means to communicate to others how a process is done

- Document a process as a recordHelps to plan a project step-by-step

Common elements often include the sequence of actions, materials or services entering or leaving the process (inputs and outputs), decisions that must be made, and people or functions who are involved.

Anything with multiple steps can be flow charted: e.g., a manufacturing process, a repair activity, an administrative process, a project plan. PFDs are generic tools that can be adapted for a wide variety of purposes. Here are the steps:

- To develop a PFD, accumulate a small team to analyze the process. Make sure you have the right Subject Matter Experts (SME) in the room. Attempting to develop steps and decisions without knowledgeable people can result in a poor end product.

- Gather the materials or resources. Common materials needed could be sticky notes or cards, a flowcharting software program like SmartDraw or Visio, a projection screen or a large piece of flipchart paper, or newsprint with marking pens.

- Define the process to be diagrammed. State it on the bottom or top of the diagram being developed.

- Discuss and decide on the boundaries of your process. Where or when does the process begin? Where or when does it stop? Discuss and decide on the level of detail to be included in the diagram. Agree on the symbols to be used. See Figure 1 for the four common symbols for process mapping.

- Brainstorm the activities and decisions that take place. Write each on a card or sticky note or enter as a task box on the computer. Sequence is not important at this point, although thinking in sequence may help people recall the steps.

- Arrange the activities in proper sequence.

- When all activities are included and everyone agrees that the sequence is correct, draw arrows to show the flow of the process.

- Review or validate the flowchart with others involved in the process (workers, supervisors, suppliers, or customers) to see if they agree that the process is drawn accurately.

Figure 1: The four common symbols for process mapping

SOME CONSIDERATIONS

Don’t worry too much about drawing the flowchart the “right way.” The right way is the way that helps those involved understand the process. The flowchart should be clear and easy to follow, and remember that computer software can speed up the development of flowcharts.

This in no way implies that the short order cook does not work hard; it does imply that the application of tried and true techniques applied the same way can produce a superior product less likely to require antacid half an hour later. ■

About The Author: Preston Ingalls is president and CEO of TBR Strategies, LLC, a Raleigh, North Carolina-based maintenance and reliability firm specializing in the construction and oil and gas industries. Preston can be reached at pingalls@tbr-strategies.com, or visit www.tbr-strategies.com.

_________________________________________________________________________

Modern Contractor Solutions – September 2016

Did you enjoy this article?

Subscribe to the FREE Digital Edition of Modern Contractor Solutions magazine.